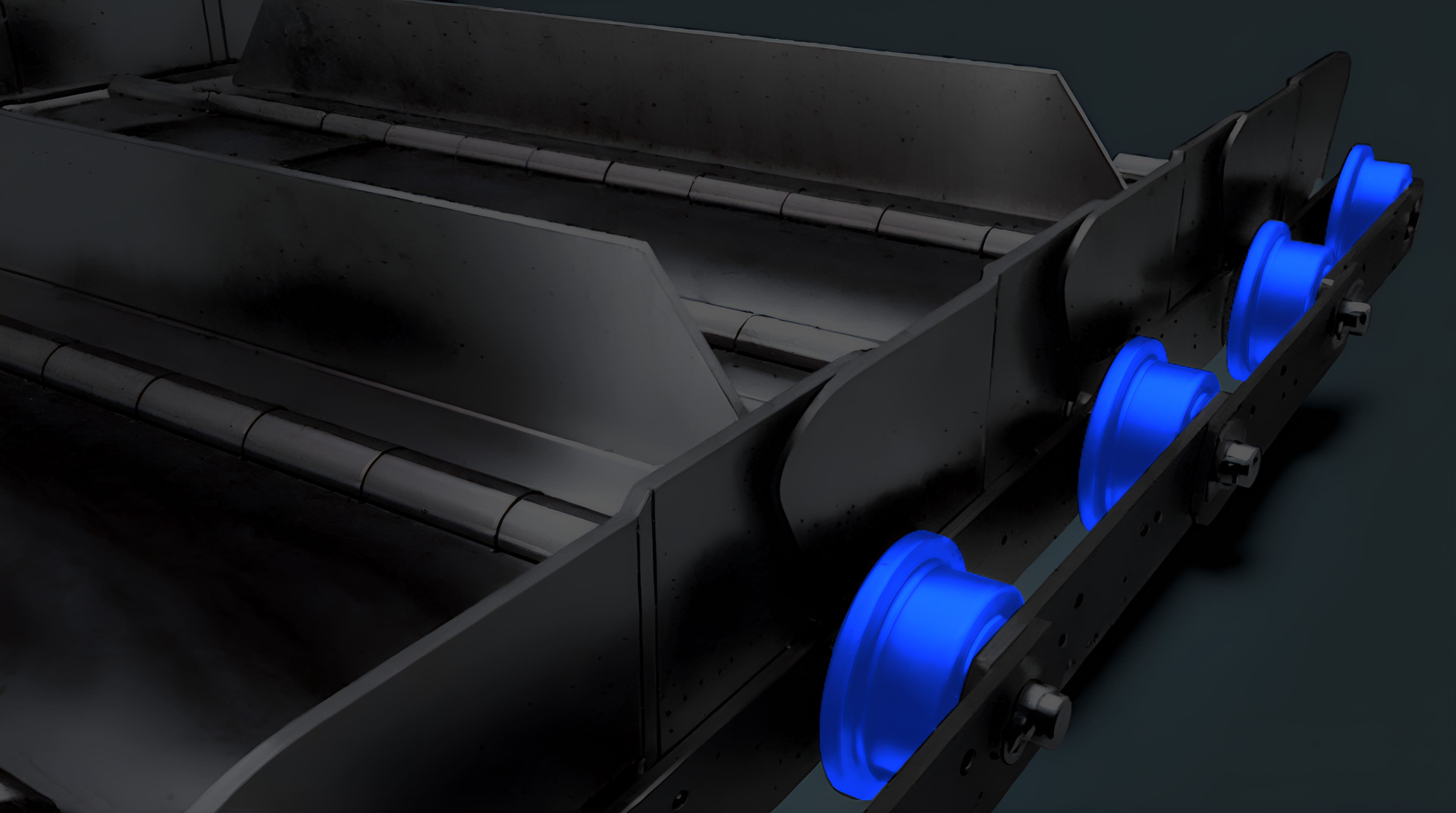

Z-PAN BELT

Created for smooth performance while carrying the brunt of a load.

Making sure your operations stay flawless through years of the most intense conditions.

Fluent Conveyors offers z-pan roller chain replacement belts so your operation can keep

moving at full speed.